Introducing our Technical Research Institute.

The products of Korea Sintered Metal Co., Ltd. lead the high-quality manufacturing industry of automobiles and home appliances both domestically and internationally, thanks to the latest automation facilities and thorough production management.

CFT Meeting

CFT Meeting

We consult with customers on their development requests.

Design Inputs

Design Inputs

We design the detailed shapes required for sintered products.

C.A.E Modeling

C.A.E Modeling

We model the designed shapes in three dimensions.

System Analysis

System Analysis

We review the system application of the product and its connectivity with other parts.

Evaluation

Evaluation

& Assessment

We comprehensively analyze evaluation figures and data.

Mechanical Testing

Mechanical Testing

& Simulation

We evaluate product characteristics with in-house analysis and evaluation equipment.

Prototypes

Prototypes

We manufacture prototypes in the same way as mass production processes.

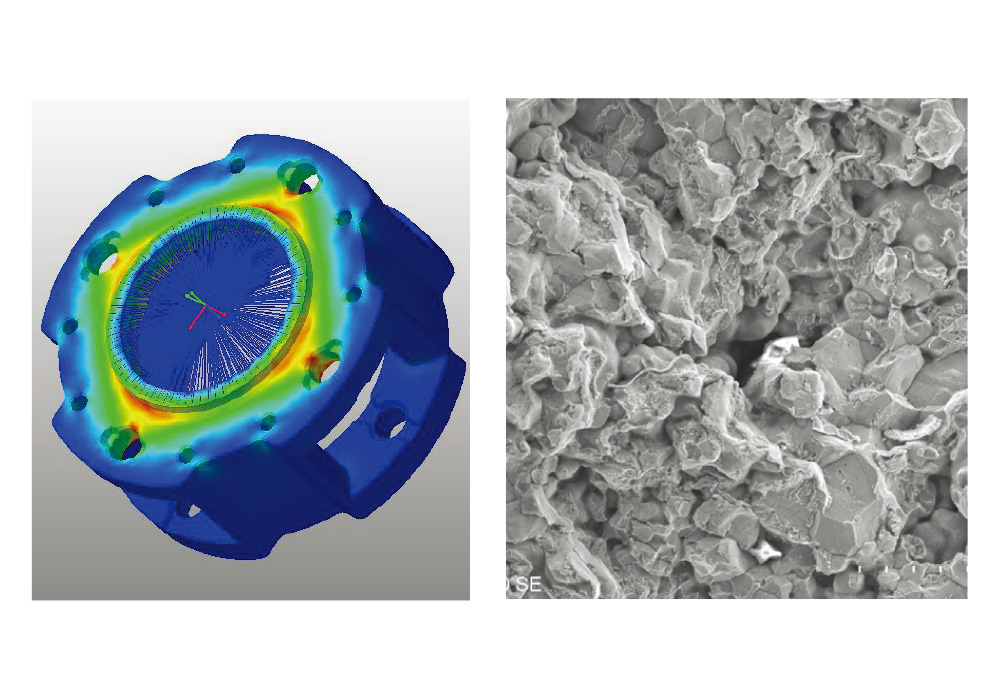

F.E.A

F.E.A

We analyze the stress applied to the product and its durability through finite element analysis (F.E.A).

Research Areas

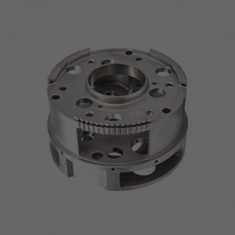

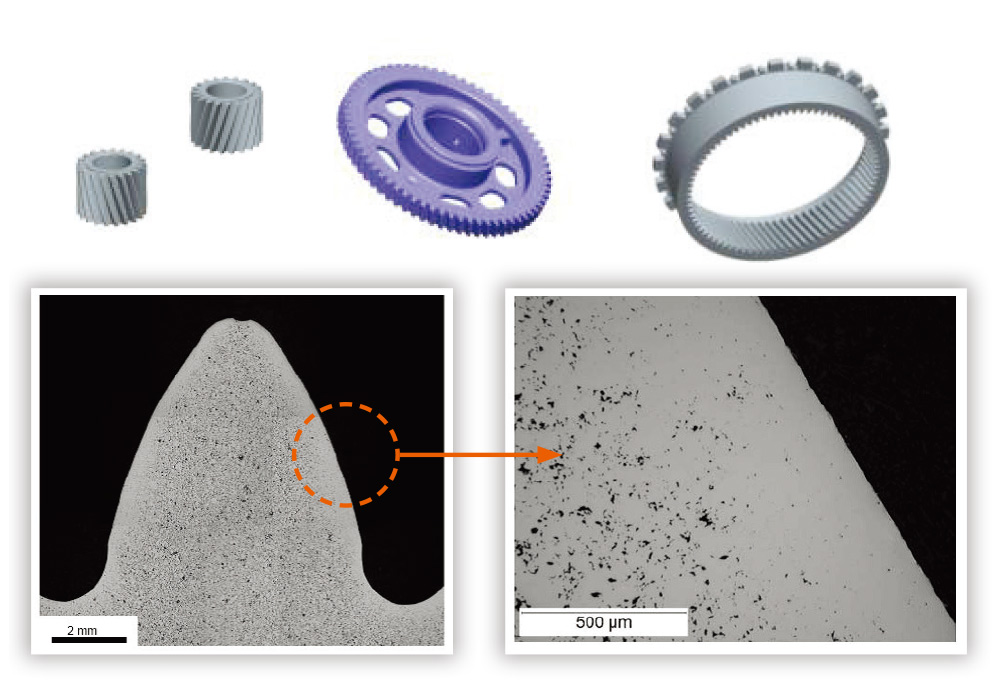

Helical Compaction

Implementing helical gears without additional machining through helical mold design technology.

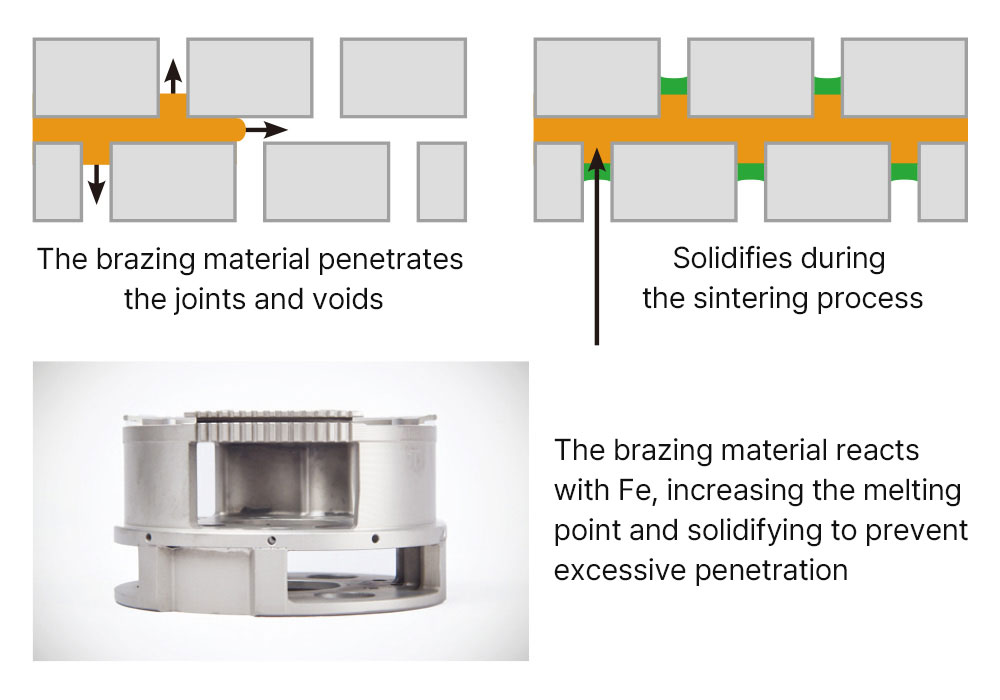

Brazing Bonding

Brazing joining technology for realizing the Net-Shape of multi-stage products with complex shapes.

Surface Densification

A technology that improves strength, wear resistance, and fatigue resistance by manufacturing sintered product surfaces close to true density without machining through surface densification technology.

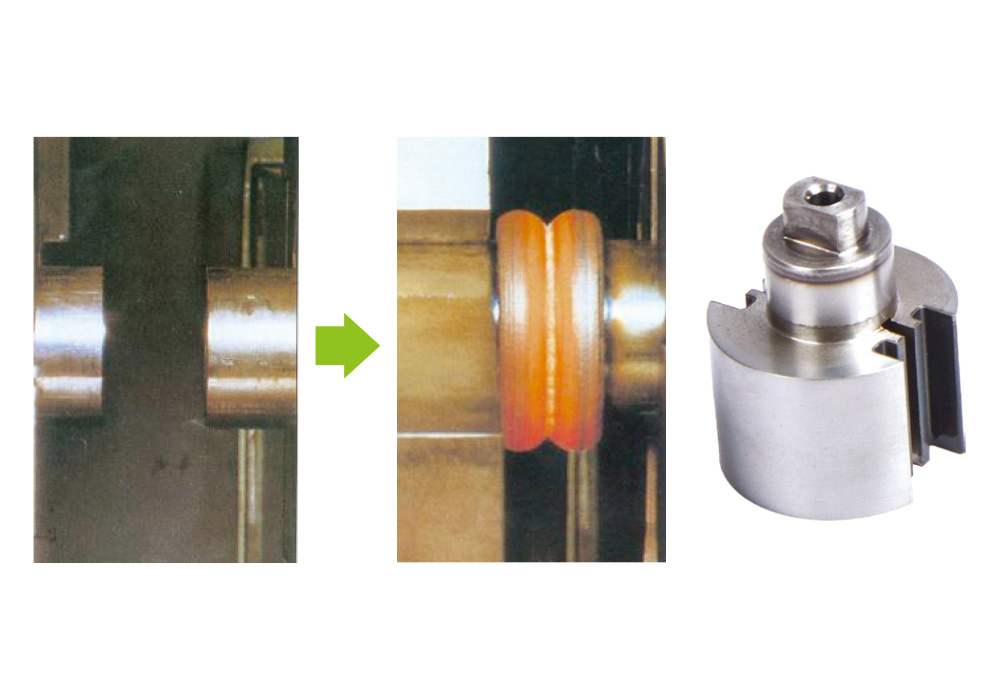

Friction Welding

A technology that joins two dissimilar materials, which are difficult to join by brazing or welding, by applying pressure and high-speed rotation to generate frictional heat.

High Strength Technology

Manufacturing high-strength parts using various technologies such as high-temperature sintering, warm forming, powder forging, and die lubrication.

Multi-Level Compaction

Manufacturing high-strength products with minimal machining using the powder transfer molding method.

Wear Resistance Materials

Manufacturing heat-resistant and wear-resistant parts by freely adding alloying elements.

Special Gear

Manufacturing low-noise, high-performance oil pump rotors through proprietary tooth profile design and development.

F.E.M & Analysis

Leading sintering technology based on a wide range of analysis experiences such as deformation, stress calculation of parts and molds using Finite Element Method (F.E.M), component analysis, wear behavior, fracture analysis.